丝杠动态扭矩怎么测

来源://www.crazwind.com/ 日期:2025-05-19 发布人:

在精密传动领域,丝杠作为核心执行元件,其动态扭矩特性直接影响机械系统的响应精度与寿命。动态扭矩测量不仅是设备调试的必经环节,更是揭示传动系统真实工作状态的关键窗口。本文将从技术本质出发,系统阐述丝杠动态扭矩的测量原理与实现路径。

In the field of precision transmission, the screw serves as the core actuator, and its dynamic torque characteristics directly affect the response accuracy and lifespan of the mechanical system. Dynamic torque measurement is not only a necessary step in equipment debugging, but also a key window to reveal the true working status of the transmission system. This article will start from the essence of technology and systematically explain the measurement principle and implementation path of dynamic torque of screw.

动态扭矩的技术内涵

The technical connotation of dynamic torque

丝杠动态扭矩指其在旋转过程中实时变化的扭矩值,包含启动扭矩、运行扭矩、摩擦扭矩等多维参数。这些参数构成传动系统的“扭矩指纹”,直接反映丝杠副的预紧状态、润滑条件及磨损程度。例如,当动态扭矩波动超过±5%时,可能预示着滚道磨损或润滑失效。

The dynamic torque of a screw refers to the real-time torque value that changes during its rotation, including multidimensional parameters such as starting torque, operating torque, and friction torque. These parameters constitute the "torque fingerprint" of the transmission system, directly reflecting the pre tightening state, lubrication conditions, and wear degree of the screw pair. For example, when the dynamic torque fluctuation exceeds ± 5%, it may indicate raceway wear or lubrication failure.

测量原理与实现路径

Measurement principle and implementation path

应变式测量技术

Strain gauge measurement technology

在丝杠轴向特定位置粘贴电阻应变片,通过惠斯通电桥将机械变形转化为电信号。四片全桥接法可轴向力干扰,使扭矩测量灵敏度达到0.1%级。为应对高速旋转工况,需采用无线遥测技术,通过旋转耦合器实现信号非接触传输,采样频率可达10kHz。

Stick resistance strain gauges at specific positions along the screw axis, and convert mechanical deformation into electrical signals through a Wheatstone bridge. The four piece full bridge method can eliminate axial force interference and achieve a torque measurement sensitivity of 0.1%. To cope with high-speed rotating conditions, wireless telemetry technology is required to achieve non-contact signal transmission through a rotary coupler, with a sampling frequency of up to 10kHz.

磁电式非接触测量

Magnetic electric non-contact measurement

基于磁弹效应原理,在丝杠表面加工微米级应力感应槽,当扭矩作用时,磁导率变化引起感应线圈电感量改变。该技术突破接触式测量的转速限制,可在3000rpm工况下稳定工作,测量带宽覆盖DC-2000Hz。

Based on the principle of magnetoelastic effect, micro scale stress induction grooves are machined on the surface of the screw. When torque is applied, the change in magnetic permeability causes a change in the inductance of the induction coil. This technology breaks through the speed limit of contact measurement and can work stably at 3000rpm, with a measurement bandwidth covering DC-2000Hz.

激光多普勒测扭法

Laser Doppler torsion measurement method

通过激光干涉仪监测丝杠表面特定点的微位移,利用空间相位差解算扭矩值。该技术空间分辨率达微米级,特别适用于纳米级精度要求的超精密丝杠检测,但需在恒温恒湿环境下使用。

Monitor the micro displacement of specific points on the surface of the screw using a laser interferometer, and calculate the torque value using spatial phase difference. This technology has a spatial resolution of micrometers and is particularly suitable for ultra precision screw detection with nanometer level accuracy requirements, but it needs to be used in a constant temperature and humidity environment.

测量系统的核心组件

The core components of the measurement system

高精度扭矩传感器

High precision torque sensor

量程选择需覆盖额定扭矩的120%-150%,非线性度≤0.05%FS。对于动态测量,需关注传感器固有频率,应大于被测信号频率的3倍以上,避免谐振失真。

The range selection should cover 120% -150% of the rated torque, with a nonlinearity of ≤ 0.05% FS. For dynamic measurement, special attention should be paid to the natural frequency of the sensor, which should be greater than three times the highest frequency of the measured signal to avoid resonance distortion.

数据采集单元

Data collection unit

采用24位Δ-Σ型ADC,配合抗混叠滤波器,确保信号保真度。对于突发扭矩冲击,需配置瞬态记录功能,采样深度不低于16MS/s。

Using a 24 bit Δ - ∑ type ADC, combined with an anti aliasing filter, to ensure signal fidelity. For sudden torque impact, a transient recording function should be configured with a sampling depth of not less than 16MS/s.

环境干扰抑制

Environmental interference suppression

通过电磁屏蔽舱隔离工频干扰,温度补偿模块实时修正热漂移。对于振动敏感场景,采用空气弹簧隔振平台,使环境振动加速度≤0.05g。

Isolation of power frequency interference through electromagnetic shielding cabin, and real-time correction of thermal drift by temperature compensation module. For vibration sensitive scenarios, an air spring isolation platform is used to ensure that the environmental vibration acceleration is ≤ 0.05g.

测量数据的深度解析

Deep analysis of measurement data

采集的扭矩曲线需进行时频联合分析。时域分析关注平均扭矩、扭矩波动系数等参数;频域分析通过FFT变换揭示0-1000Hz频段内的特征频率成分。当出现100Hz倍频成分时,可能源于丝杠螺母副的周期性接触变形。

The collected torque curve needs to undergo time-frequency joint analysis. Time domain analysis focuses on parameters such as average torque and torque fluctuation coefficient; Frequency domain analysis reveals characteristic frequency components within the 0-1000Hz frequency range through FFT transformation. When a 100Hz harmonic component appears, it may be due to periodic contact deformation of the screw nut pair.

动态扭矩测量本质是揭示传动系统的力学语言。通过高精度测量与深度数据分析,可建立丝杠的数字孪生模型,为传动设计优化、剩余寿命预测提供数据支撑。这种技术能力正在推动精密制造装备向更智能、更可靠的方向演进。

The essence of dynamic torque measurement is to reveal the mechanical language of the transmission system. Through high-precision measurement and depth data analysis, a digital twin model of the screw can be established to provide data support for transmission design optimization and remaining life prediction. This technological capability is driving the evolution of precision manufacturing equipment towards smarter and more reliable directions.

本文由pg电子游戏太阳神传说 友情奉献.更多有关的知识请点击://www.crazwind.com真诚的态度.为您提供为的服务.更多有关的知识我们将会陆续向大家奉献.敬请期待.

This article is a friendly contribution from the guide screw For more information, please click: //www.crazwind.com Sincere attitude To provide you with comprehensive services We will gradually contribute more relevant knowledge to everyone Coming soon.

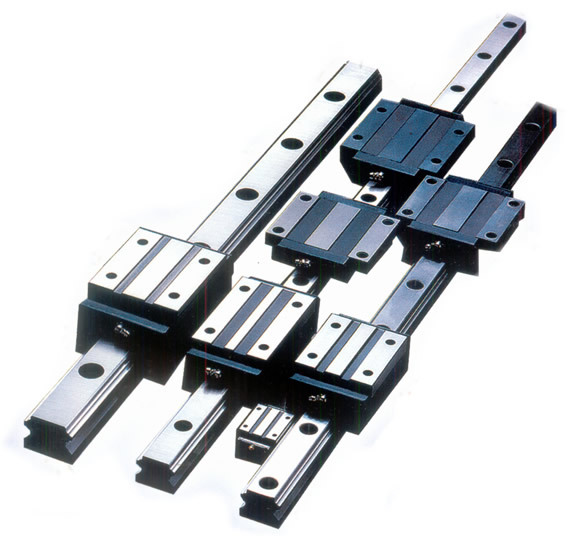

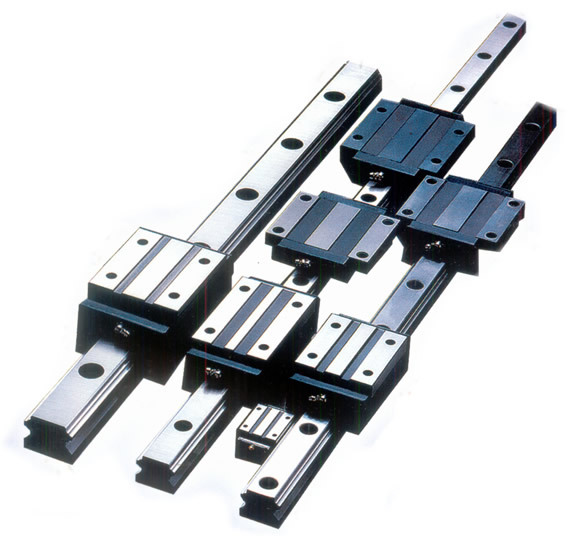

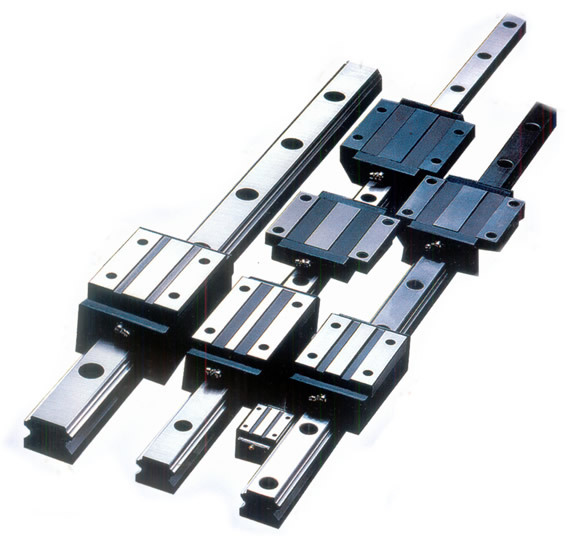

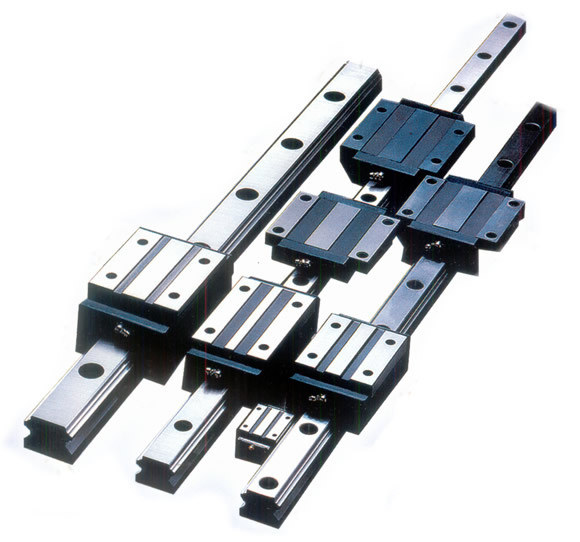

- 上一篇:解析导轨抗磨损涂层技术

- 下一篇:导轨抗腐蚀材料有哪些:构建长效防护的材料体系

导轨抗腐蚀材料有哪些...<>

导轨抗腐蚀材料有哪些...<> 丝杠动态扭矩怎么测<>

丝杠动态扭矩怎么测<> 解析导轨抗磨损涂层技...<>

解析导轨抗磨损涂层技...<> 解析导轨运行平稳度标...<>

解析导轨运行平稳度标...<> 丝杠动态刚度怎么测?<>

丝杠动态刚度怎么测?<>