导轨防腐蚀措施有哪些?

来源://www.crazwind.com/ 日期:2025-07-11 发布人:

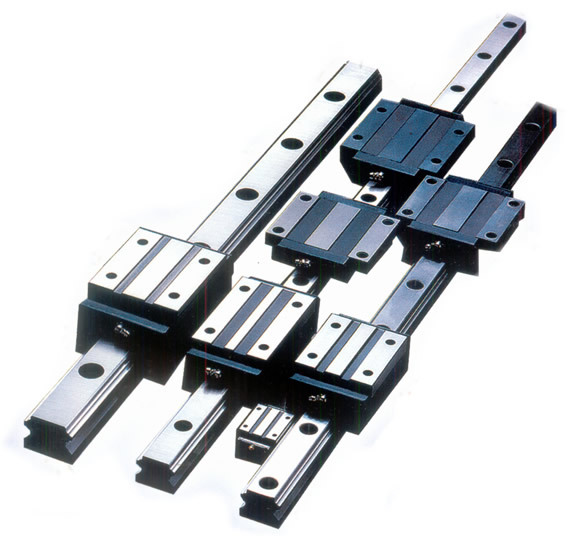

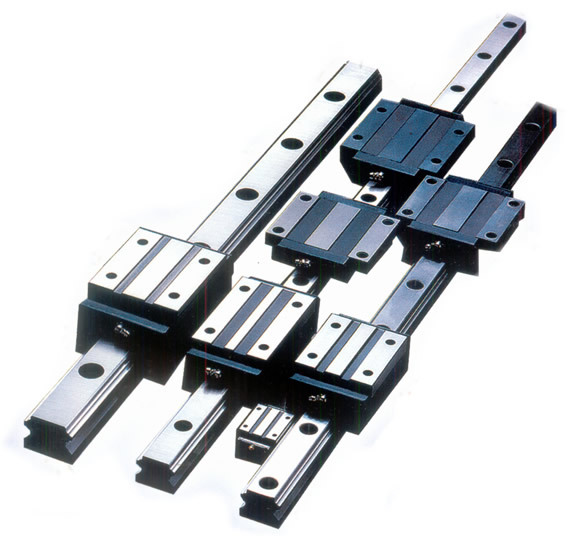

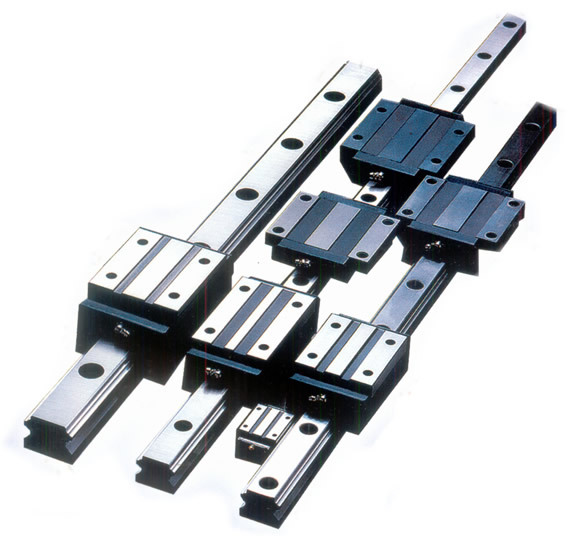

导轨作为机械运行的关键部件,长期暴露在潮湿、多尘或有化学介质的环境中,极易发生腐蚀,影响设备精度和使用寿命。合理的防腐蚀措施需结合使用环境与导轨材质,从材料优化、表面处理到日常维护,构建的防护体系。

As a key component of mechanical operation, guide rails are highly susceptible to corrosion when exposed to damp, dusty, or chemical media environments for a long time, which can affect equipment accuracy and service life. Reasonable anti-corrosion measures need to be combined with the usage environment and guide rail materials, from material optimization, surface treatment to daily maintenance, to build a comprehensive protection system.

材料选择是防腐蚀的基础。对于潮湿环境(如食品加工车间、户外设备),优先选用耐腐蚀合金材质,如 304 不锈钢导轨,其含铬量达 18% 以上,能在表面形成致密氧化膜,抵御水和氧气侵蚀,盐雾测试中可保持 500 小时无锈蚀。在有酸碱腐蚀的场景(如化工设备),则需选用 316 不锈钢,添加 2%-3% 的钼元素,增强对氯离子的抵抗能力,适用于海边或含盐水雾环境。对于承重较大的导轨,可采用碳钢基体表面渗铝处理,渗铝层厚度达 0.1-0.2 毫米,形成类似铝合金的耐腐蚀表层,兼顾强度与耐腐蚀性。

Material selection is the foundation of corrosion prevention. For humid environments such as food processing workshops and outdoor equipment, corrosion-resistant alloy materials are preferred, such as 304 stainless steel guide rails, which have a chromium content of over 18% and can form a dense oxide film on the surface to resist water and oxygen erosion. They can maintain rust free for 500 hours in salt spray testing. In scenarios with acid and alkali corrosion (such as chemical equipment), 316 stainless steel should be selected, with 2% -3% molybdenum added to enhance resistance to chloride ions, suitable for coastal or salt water mist environments. For guide rails with large load-bearing capacity, carbon steel substrate surface aluminum infiltration treatment can be used, with an aluminum infiltration layer thickness of 0.1-0.2 millimeters, forming a corrosion-resistant surface layer similar to aluminum alloy, balancing strength and corrosion resistance.

表面处理技术能显著提升抗腐蚀能力。电镀工艺中,硬铬镀层(厚度 5-15 微米)是常用选择,镀层硬度达 800-1000HV,不仅耐磨,还能隔绝基体与腐蚀介质,适合机械加工设备的导轨。对于要求更高的场景,可采用化学镀镍磷合金,镀层均匀无针孔,耐中性盐雾性能超过 1000 小时,且与基体结合力强,不易脱落。喷涂处理则适用于大型导轨,通过静电喷涂氟碳涂料(厚度 30-50 微米),利用氟树脂的化学惰性,抵御酸碱和有机溶剂侵蚀,同时具备良好的耐候性,户外使用可保持 10 年以上不褪色、不粉化。

Surface treatment technology can significantly enhance corrosion resistance. In the electroplating process, hard chromium coating (thickness 5-15 microns) is a commonly used choice, with a hardness of 800-1000HV. It is not only wear-resistant, but also can isolate the substrate from corrosive media, making it suitable for the guide rails of mechanical processing equipment. For scenarios with higher requirements, chemical nickel phosphorus alloy can be used, with a uniform and pinhole free coating, a neutral salt spray resistance of over 1000 hours, and strong adhesion to the substrate, making it difficult to peel off. Spray treatment is suitable for large guide rails, using electrostatic spraying of fluorocarbon coating (thickness 30-50 microns), utilizing the chemical inertness of fluororesin to resist acid, alkali, and organic solvent erosion, while also having good weather resistance. It can be used outdoors for more than 10 years without fading or powdering.

密封与隔离设计阻断腐蚀介质接触。在导轨与外界环境间加装防护罩,如伸缩式风琴防护罩,采用耐油橡胶布或尼龙布制成,能随导轨运动伸缩,防止粉尘、水汽进入。对于液体飞溅环境(如机床冷却系统),可在导轨侧面安装橡胶密封条,密封条与导轨面紧密贴合,压缩量控制在 2-3 毫米,既不影响运动精度,又能阻挡冷却液渗入。在湿度较高的场所,还可在导轨安装腔体内放置干燥剂(如硅胶干燥剂,每立方米空间放置 50-100 克),降低局部空气湿度,避免冷凝水形成。

Sealing and isolation design blocks contact with corrosive media. Install a protective cover between the guide rail and the external environment, such as a retractable accordion protective cover made of oil resistant rubber cloth or nylon cloth, which can expand and contract with the movement of the guide rail to prevent dust and water vapor from entering. For liquid splashing environments (such as machine tool cooling systems), rubber sealing strips can be installed on the side of the guide rail. The sealing strips are tightly attached to the guide rail surface, and the compression amount is controlled at 2-3 millimeters, which does not affect the motion accuracy and can block the infiltration of coolant. In places with high humidity, desiccants (such as silica gel desiccants, with 50-100 grams per cubic meter of space) can be placed inside the guide rail installation chamber to reduce local air humidity and avoid condensation.

电化学保护适用于特定场景的长效防护。对于埋地或浸入液体中的导轨(如水利设备导轨),可采用牺牲阳极法,在导轨附近连接锌块或镁块,利用锌、镁的活性高于铁的特性,优先发生氧化反应,保护导轨基体不被腐蚀,阳极块每 1-2 年更换一次,根据腐蚀速率调整更换周期。外加电流阴极保护则适用于大型设备,通过直流电源使导轨成为阴极,抑制其电化学腐蚀,电流密度控制在 0.1-0.5 毫安 / 平方厘米,需定期检测电极状态,确保保护效果稳定。

Electrochemical protection is suitable for long-term protection in specific scenarios. For guide rails buried underground or immersed in liquids (such as water conservancy equipment guide rails), sacrificial anode method can be used to connect zinc or magnesium blocks near the guide rails. By utilizing the higher activity of zinc and magnesium than iron, oxidation reaction occurs first to protect the guide rail substrate from corrosion. The anode block is replaced every 1-2 years, and the replacement cycle is adjusted according to the corrosion rate. External current cathodic protection is suitable for large equipment, which uses a DC power supply to turn the guide rail into a cathode and suppress its electrochemical corrosion. The current density is controlled at 0.1-0.5 milliampere per square centimeter, and the electrode status needs to be regularly checked to ensure stable protection effect.

日常维护是防腐蚀的重要补充。定期清理导轨表面的油污、粉尘,用中性清洁剂(如肥皂水)擦拭,避免使用强酸强碱清洗剂,防止破坏表面防护层。清理后涂抹专用防锈油(如锂基防锈脂),油膜厚度保持 5-10 微米,形成润滑与防护双重作用,每月少涂抹一次,潮湿环境需增加频次。对于长期停用的导轨,需进行彻底清洁后,用防锈纸包裹或涂覆可剥性塑料,塑料膜厚度 0.2-0.3 毫米,形成密封保护层,防止存放期间锈蚀。

Daily maintenance is an important supplement to corrosion prevention. Regularly clean the oil and dust on the surface of the guide rail, wipe it with a neutral cleaning agent (such as soapy water), avoid using strong acid and alkali cleaning agents, and prevent damage to the surface protective layer. After cleaning, apply specialized anti rust oil (such as lithium based anti rust grease) with a film thickness of 5-10 microns, forming a dual function of lubrication and protection. Apply at least once a month, and increase the frequency in humid environments. For guide rails that have been out of use for a long time, they need to be thoroughly cleaned and wrapped or coated with rust proof paper or peelable plastic with a plastic film thickness of 0.2-0.3 millimeters to form a sealed protective layer to prevent rusting during storage.

本文由pg电子游戏太阳神传说 友情奉献.更多有关的知识请点击://www.crazwind.com真诚的态度.为您提供为的服务.更多有关的知识我们将会陆续向大家奉献.敬请期待.

This article is a friendly contribution from the guide screw For more information, please click: //www.crazwind.com Sincere attitude To provide you with comprehensive services We will gradually contribute more relevant knowledge to everyone Coming soon.

- 上一篇:滚珠丝杠的循环方式解析

- 下一篇:

导轨防腐蚀措施有哪些...<>

导轨防腐蚀措施有哪些...<> 滚珠丝杠的循环方式解...<>

滚珠丝杠的循环方式解...<> 导轨丝杆在陶瓷雕铣机...<>

导轨丝杆在陶瓷雕铣机...<> 导轨运行阻力怎么测量...<>

导轨运行阻力怎么测量...<> 丝杠传动中的回差现象...<>

丝杠传动中的回差现象...<>