丝杠导程精度怎么测?

来源://www.crazwind.com/ 日期:2025-06-11 发布人:

丝杠导程精度是衡量传动系统性能的核心指标,直接影响数控机床、自动化设备及精密仪器的定位准确性与运动平稳性。其测量需结合工具与标准化流程,通过量化误差数据为设备调校、质量评估及故障诊断提供依据。

The lead accuracy of the screw is the core indicator for measuring the performance of the transmission system, which directly affects the positioning accuracy and motion stability of CNC machine tools, automation equipment, and precision instruments. Its measurement needs to be combined with professional tools and standardized processes, providing a basis for equipment calibration, quality assessment, and fault diagnosis through quantitative error data.

一、测量原理与核心目标

1、 Measurement Principles and Core Objectives

丝杠导程精度指螺母沿丝杠轴线移动一周的理论位移与实际位移的偏差。测量需捕捉两参数:

The lead accuracy of the screw refers to the deviation between the theoretical displacement and the actual displacement of the nut moving along the screw axis for one revolution. Measurement requires capturing two parameters:

理论导程:由丝杠螺距与头数决定,如双头丝杠导程为单头螺距的两倍。

Theoretical lead: determined by the pitch of the screw and the number of heads, for example, the lead of a double headed screw is twice the pitch of a single headed screw.

实际位移:通过高精度传感器实时采集螺母移动距离,结合角度编码器记录丝杠旋转角度,计算实际导程值。

Actual displacement: Real time collection of nut movement distance through high-precision sensors, combined with angle encoder recording of screw rotation angle, and calculation of actual lead value.

二、常用测量工具与技术参数

2、 Common measuring tools and technical parameters

激光干涉仪:

Laser interferometer:

原理:利用激光波长稳定性,测量线性位移误差。

Principle: Utilizing laser wavelength stability to measure linear displacement error.

精度:可达±0.1μm,适用于超精密丝杠检测。

Accuracy: up to ± 0.1 μ m, suitable for ultra precision screw detection.

应用:配合环境补偿系统,温度、气压波动影响。

Application: In conjunction with an environmental compensation system, eliminate the effects of temperature and pressure fluctuations.

丝杠专用测量仪:

Screw specific measuring instrument:

结构:集成双频激光测长基准与圆光栅角度基准,如北京机床研究所JCS系列。

Structure: Integrated dual frequency laser length measurement reference and circular grating angle reference, such as the JCS series from Beijing Machine Tool Research Institute.

功能:实时输出误差曲线,自动计算平均行程偏差(ea)、行程变动量(Vua、V300a)。

Function: Real time output of error curve, automatic calculation of average travel deviation (ea) and travel variation (Vua, V300a).

测量范围:支持2-12米长丝杠,精度分级覆盖1-5级。

Measurement range: Supports 2-12-meter long lead screws, with precision grading covering levels 1-5.

光栅尺与编码器组合:

Combination of grating ruler and encoder:

光栅尺:测量直线位移,分辨率达5μm。

Grating ruler: measures linear displacement with a resolution of 5 μ m.

编码器:记录丝杠旋转角度,同步数据采集卡信号。

Encoder: Record the rotation angle of the screw and synchronize the data acquisition card signal.

优势:成本较低,适用于现场快速检测。

Advantages: Low cost, suitable for rapid on-site testing.

三、标准化测量流程

3、 Standardized measurement process

预处理阶段:

Preprocessing stage:

清洁丝杠表面,去除油污与颗粒物。

Clean the surface of the screw to remove oil stains and particulate matter.

固定丝杠于恒温平台,调整同轴度≤0.01mm,垂直度≤0.02mm。

Fix the screw on the constant temperature platform, adjust the coaxiality to ≤ 0.01mm and perpendicularity to ≤ 0.02mm.

传感器安装:

Sensor installation:

激光干涉仪反射镜固定于工作台,光路对准丝杠轴线。

The reflector of the laser interferometer is fixed on the workbench, and the optical path is aligned with the axis of the screw.

光栅尺沿导轨平行布置,编码器与丝杠端部联轴器连接。

The grating ruler is arranged parallel to the guide rail, and the encoder is connected to the coupling at the end of the screw.

数据采集:

Data collection:

驱动丝杠以5-30rpm匀速旋转,同步记录角度与位移数据。

Drive the screw to rotate at a constant speed of 5-30rpm, synchronously recording angle and displacement data.

采样频率≥1000Hz,覆盖有效行程3-5次。

Sampling frequency ≥ 1000Hz, covering effective travel 3-5 times.

误差分析:

Error analysis:

生成误差曲线,标定峰值偏差与周期性误差成分。

Generate error curves, calibrate peak deviation and periodic error components.

计算ea(实际平均行程偏差)、V2πa(每转行程变动量)。

Calculate ea (actual average travel deviation) and V2 π a (change in travel per revolution).

结果判定:

Result judgment:

对比GB/T 17587.3-1998标准,确定精度等级。

Compare the GB/T 17587.3-1998 standard to determine the accuracy level.

示例:某滚珠丝杠ea=+3μm,V2πa=2μm,符合1级精度要求。

Example: A ball screw with ea=+3 μ m and V2 π a=2 μ m meets the requirements of Level 1 accuracy.

四、关键影响因素与控制措施

4、 Key influencing factors and control measures

环境因素:

Environmental factors:

温度控制:恒温车间20℃±1℃,避免热变形。

Temperature control: Constant temperature workshop at 20 ℃± 1 ℃ to avoid thermal deformation.

振动隔离:采用气浮导轨或减震平台,抑制外部干扰。

Vibration isolation: using air floating guide rails or shock-absorbing platforms to suppress external interference.

安装误差:

Installation error:

同轴度调整:使用激光对准仪,确保丝杠轴线与导轨平行。

Coaxiality adjustment: Use a laser alignment device to ensure that the screw axis is parallel to the guide rail.

工作台跳动:千分表检测≤0.005mm,否则需重新调校。

Workbench jumping: The micrometer detection is ≤ 0.005mm, otherwise it needs to be recalibrated.

工具校准:

Tool calibration:

激光干涉仪定期溯源计量标准。

Laser interferometers are regularly traced back to national metrological standards.

光栅尺与编码器进行交叉验证,系统误差。

Cross validation between grating ruler and encoder to eliminate system errors.

本文由pg电子游戏太阳神传说 友情奉献.更多有关的知识请点击://www.crazwind.com真诚的态度.为您提供为的服务.更多有关的知识我们将会陆续向大家奉献.敬请期待.

This article is a friendly contribution from the guide screw For more information, please click: //www.crazwind.com Sincere attitude To provide you with comprehensive services We will gradually contribute more relevant knowledge to everyone Coming soon.

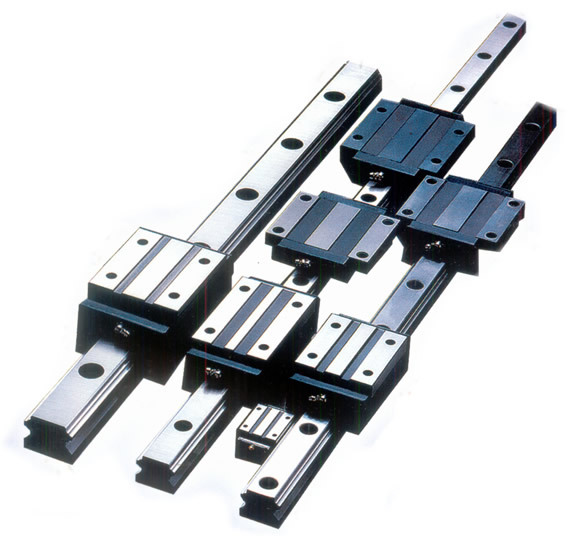

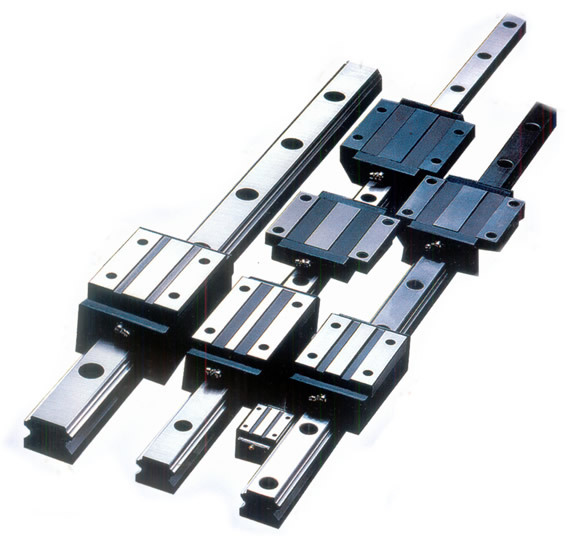

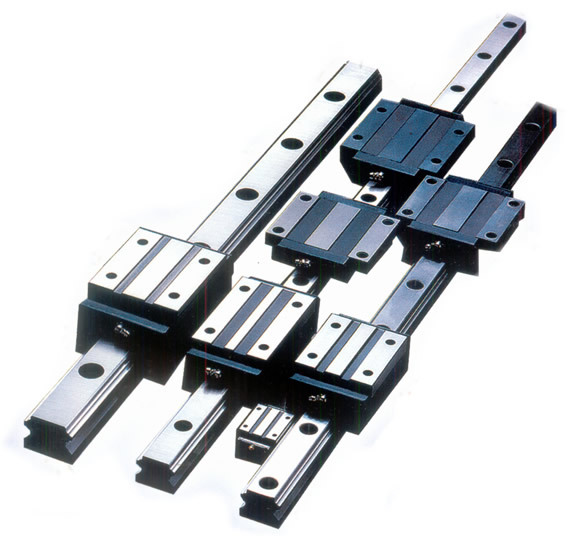

- 上一篇:导轨有哪些种类?

- 下一篇:导轨防松措施有哪些?

导轨抗腐蚀材料有哪些...<>

导轨抗腐蚀材料有哪些...<> 丝杠制作过程解析<>

丝杠制作过程解析<> 丝杠动态刚度怎么检...<>

丝杠动态刚度怎么检...<> 导轨防腐蚀措施有哪些...<>

导轨防腐蚀措施有哪些...<> 滚珠丝杠的循环方式解...<>

滚珠丝杠的循环方式解...<>