解锁导轨 “丝滑舞步”:润滑方式的多样秘籍

来源://www.crazwind.com/ 日期:2025-06-18 发布人:

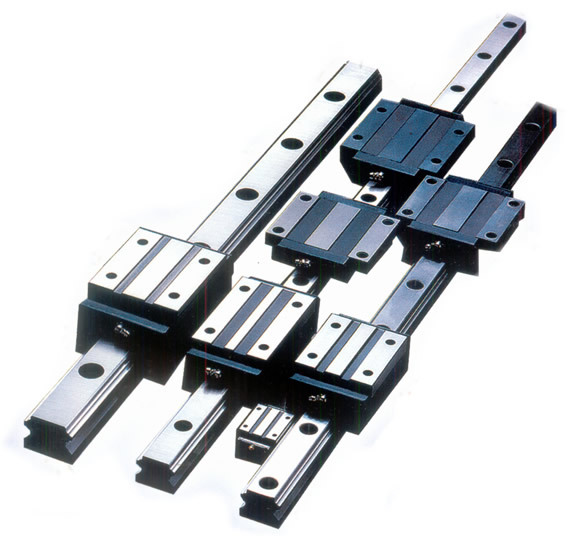

在机械运动的舞台上,导轨如同精密仪器的 “舞者”,引导部件准确移动。而润滑,则是让这些 “舞者” 跳出流畅舞步的关键秘诀。合适的润滑方式不仅能降低摩擦、减少磨损,还能延长导轨使用寿命,提升设备整体性能。从传统方法到现代技术,导轨润滑的多样方式各有千秋,共同为机械运转保驾护航。

On the stage of mechanical motion, guide rails act as "dancers" of precision instruments, guiding components to move accurately. And lubrication is the key secret to making these 'dancers' dance smoothly. The appropriate lubrication method can not only reduce friction and wear, but also extend the service life of the guide rail and improve the overall performance of the equipment. From traditional methods to modern technology, various ways of lubricating guide rails have their own advantages, working together to safeguard the operation of machinery.

常见的润滑方式当属油脂润滑,它就像给导轨穿上一层 “柔软铠甲”。润滑脂是由基础油、增稠剂和添加剂混合而成的半固体状物质,具有良好的粘附性,能紧密附着在导轨表面,形成持久的保护膜。在使用时,通过手动涂抹或专用的油脂加注设备,将润滑脂均匀涂抹在导轨的滑动面、滚动体与滚道接触处等关键部位。这种方式适用于低速、重载或对密封要求较高的场合,比如大型机床的导轨。因为润滑脂不易流失,能在导轨表面长时间保持润滑效果,有效隔绝灰尘、水分等杂质的侵入,防止导轨生锈和磨损。但油脂润滑也存在局限性,随着设备运行,润滑脂会逐渐老化变干,需要定期补充或更换,以维持其润滑性能。

The most common lubrication method is grease lubrication, which is like putting a layer of "soft armor" on the guide rail. Lubricating grease is a semi-solid substance composed of base oil, thickeners, and additives, which has good adhesion and can tightly adhere to the surface of the guide rail, forming a durable protective film. When in use, lubricating grease should be evenly applied to key areas such as the sliding surface of the guide rail, the contact between the rolling elements and the raceway through manual application or specialized grease filling equipment. This method is suitable for low-speed, heavy-duty, or high sealing requirements, such as the guide rails of large machine tools. Because the lubricating grease is not easily lost, it can maintain its lubricating effect on the surface of the guide rail for a long time, effectively isolating impurities such as dust and moisture from entering, and preventing the guide rail from rusting and wearing. However, grease lubrication also has limitations. As the equipment operates, the grease will gradually age and dry out, requiring regular replenishment or replacement to maintain its lubrication performance.

油液润滑则为导轨带来更为灵动的 “滋养”。油液润滑可分为手动油壶注油、油杯滴油、压力油润滑等多种形式。手动油壶注油是较为简单的方式,操作人员定期用注油壶将润滑油注入导轨的润滑孔,这种方法适用于小型设备或润滑频率不高的导轨,但人工操作的及时性和准确性难以保证。油杯滴油通过油杯的虹吸原理,让润滑油缓慢滴落到导轨表面,能实现持续、微量的润滑,常用于一些对润滑要求不太高的普通机械。而压力油润滑则依靠液压泵将润滑油以一定压力输送到导轨的各个润滑点,这种方式润滑效果好、效率高,适用于高速、高精度的导轨系统,如数控机床的直线导轨。压力油润滑不仅能有效降低摩擦,还能带走导轨在运动过程中产生的热量,起到冷却作用,确保导轨在稳定的温度下工作。不过,油液润滑需要配备专门的油路系统和储油装置,成本相对较高,而且油液容易泄漏,对环境和设备清洁度有一定影响。

Oil lubrication brings more dynamic nourishment to the guide rail. Oil lubrication can be divided into various forms such as manual oil pot filling, oil cup dripping, and pressure oil lubrication. Manual oiling is a relatively simple method, and operators regularly use oiling pots to inject lubricating oil into the lubrication holes of the guide rails. This method is suitable for small equipment or guide rails with low lubrication frequency, but the timeliness and accuracy of manual operation are difficult to guarantee. The oil cup drips oil through the siphon principle of the oil cup, allowing the lubricating oil to slowly drip onto the surface of the guide rail, achieving continuous and minimal lubrication. It is commonly used in some ordinary machinery that does not require high lubrication. Pressure oil lubrication relies on hydraulic pumps to deliver lubricating oil to various lubrication points on the guide rail at a certain pressure. This method has good lubrication effect and high efficiency, and is suitable for high-speed and high-precision guide rail systems, such as the linear guide rail of CNC machine tools. Pressure oil lubrication can not only effectively reduce friction, but also take away the heat generated by the guide rail during movement, playing a cooling role and ensuring that the guide rail works at a stable temperature. However, oil lubrication requires a specialized oil system and storage device, which is relatively expensive, and the oil is prone to leakage, which has a certain impact on the environment and equipment cleanliness.

自润滑材料的应用为导轨润滑开辟了新路径,堪称导轨的 “智能伙伴”。自润滑材料是将固体润滑剂均匀分散在金属、塑料等基体材料中制成的复合材料。常见的有镶嵌固体润滑剂的自润滑轴承、自润滑导轨板等。这些材料中的固体润滑剂,如石墨、二硫化钼等,在导轨运动过程中会逐渐释放出来,在摩擦表面形成润滑膜,从而实现无油润滑。自润滑材料无需频繁添加润滑剂,维护简单,特别适合在一些无法或不便进行常规润滑的特殊场合使用,如高温、低温、真空、强腐蚀等极端环境下的导轨。此外,自润滑材料还具有摩擦系数低、耐磨性能好的特点,能有效延长导轨的使用寿命,减少设备停机维护时间。

The application of self-lubricating materials has opened up a new path for rail lubrication and can be regarded as the "intelligent partner" of rails. Self lubricating materials are composite materials made by uniformly dispersing solid lubricants in matrix materials such as metals and plastics. Common examples include self-lubricating bearings embedded with solid lubricants, self-lubricating guide plates, etc. The solid lubricants in these materials, such as graphite and molybdenum disulfide, will gradually be released during the movement of the guide rail, forming a lubricating film on the friction surface, thus achieving oil-free lubrication. Self lubricating materials do not require frequent addition of lubricants, are easy to maintain, and are particularly suitable for use in special situations where conventional lubrication is not possible or inconvenient, such as rails in extreme environments such as high temperature, low temperature, vacuum, and strong corrosion. In addition, self-lubricating materials also have the characteristics of low friction coefficient and good wear resistance, which can effectively extend the service life of guide rails and reduce equipment downtime for maintenance.

油气润滑作为一种的润滑技术,为导轨带来了 “精准呵护”。它将少量的润滑油与压缩空气混合后,以极细的油滴形式输送到导轨的润滑点。油气润滑的优点在于能精确控制润滑油的供给量,避免了润滑油的浪费,同时压缩空气的流动还能起到清洁导轨表面的作用,防止杂质堆积。与传统的油液润滑相比,油气润滑的润滑效果更好,能显著降低导轨的摩擦和磨损,尤其适用于高速、重载且对润滑要求苛刻的导轨系统,如高速加工中心的导轨。而且,油气润滑系统的密封性好,油雾少,对环境友好,符合现代工业绿色的发展趋势。

Oil air lubrication, as an advanced lubrication technology, brings precise care to guide rails. It mixes a small amount of lubricating oil with compressed air and delivers it in the form of extremely fine oil droplets to the lubrication points of the guide rail. The advantage of oil air lubrication is that it can accurately control the supply of lubricating oil, avoiding the waste of lubricating oil. At the same time, the flow of compressed air can also clean the surface of the guide rail and prevent the accumulation of impurities. Compared with traditional oil lubrication, oil air lubrication has better lubrication effect and can significantly reduce the friction and wear of guide rails, especially suitable for high-speed, heavy-duty and lubrication demanding guide rail systems, such as the guide rails of high-speed machining centers. Moreover, the oil air lubrication system has good sealing performance, less oil mist, is environmentally friendly, and conforms to the development trend of modern industrial green environmental protection.

导轨润滑方式如同一场丰富多彩的 “润滑盛宴”,从传统的油脂、油液润滑到创新的自润滑材料应用和的油气润滑技术,每种方式都有其独特的优势和适用场景。根据导轨的工作条件、设备要求和使用环境,选择合适的润滑方式,才能让导轨在机械运动中始终保持 “丝滑舞步”,为设备的稳定运行和生产奠定坚实基础。

The lubrication methods of guide rails are like a rich and colorful "lubrication feast", from traditional grease and oil lubrication to innovative self-lubricating material applications and advanced oil air lubrication technology, each method has its unique advantages and applicable scenarios. According to the working conditions, equipment requirements, and usage environment of the guide rail, selecting the appropriate lubrication method is necessary to ensure that the guide rail maintains a "silky smooth step" during mechanical motion, laying a solid foundation for the stable operation and efficient production of the equipment.

本文由pg电子游戏太阳神传说 友情奉献.更多有关的知识请点击://www.crazwind.com真诚的态度.为您提供为的服务.更多有关的知识我们将会陆续向大家奉献.敬请期待.

This article is a friendly contribution from the guide screw For more information, please click: //www.crazwind.com Sincere attitude To provide you with comprehensive services We will gradually contribute more relevant knowledge to everyone Coming soon.

pg电子游戏太阳神传说 相关解析<>

pg电子游戏太阳神传说 相关解析<> 丝杠动态扭矩的测量方...<>

丝杠动态扭矩的测量方...<> 导轨承载方向的确定方...<>

导轨承载方向的确定方...<> 导轨常用的抗腐蚀材料...<>

导轨常用的抗腐蚀材料...<> 导轨滑块游隙怎么调?<>

导轨滑块游隙怎么调?<>